ตัวอย่างผลงาน

-

BOTHONG RUBBER

Project Engineering Aqua Nishihara Corporation Limited

Project Name : BOTHONG RUBBER

Flow Rate : 3,000 cubic meters / day

Featured : Turnkey (Design,M&E,Startup,Operation&Training)

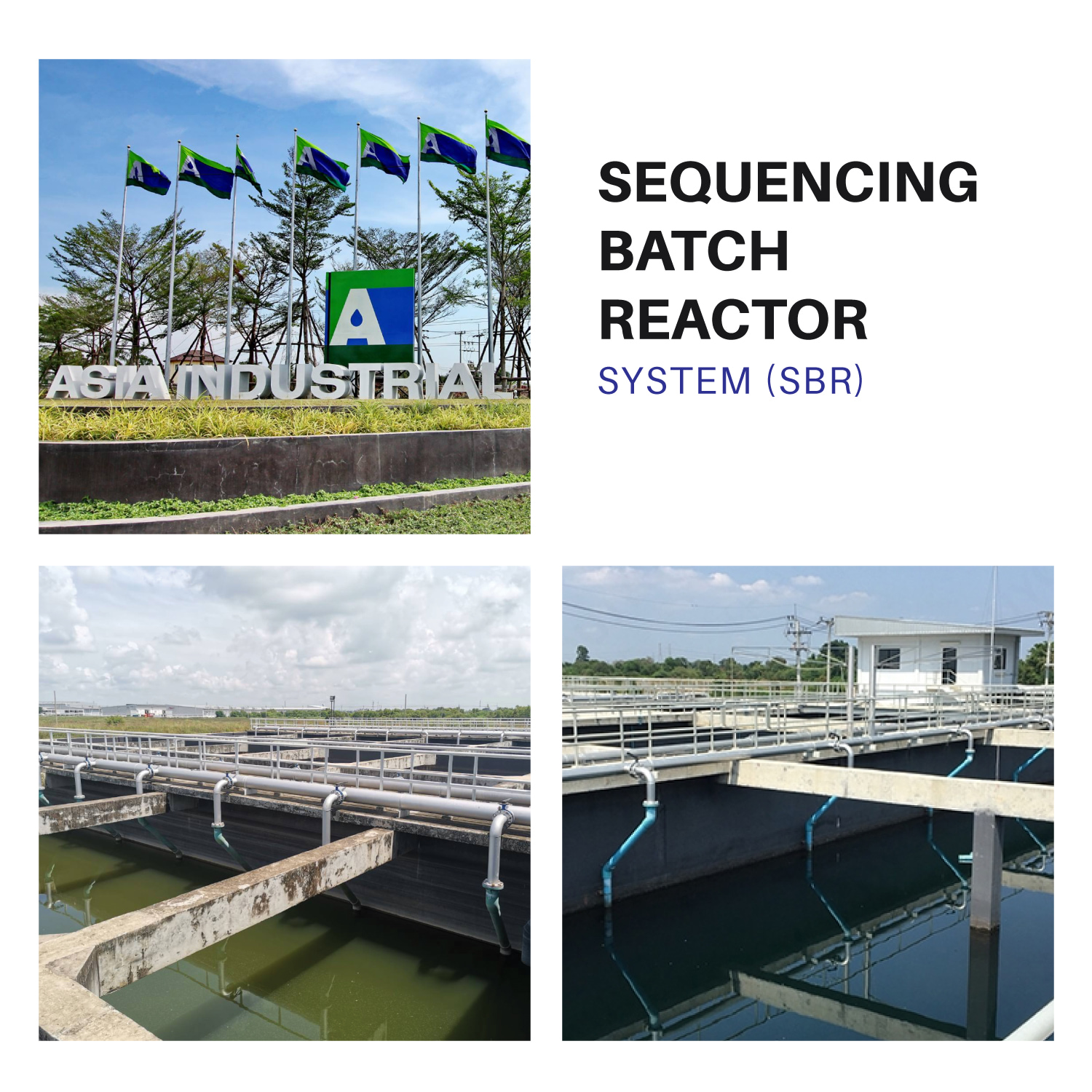

Technical : Anaerobic Baffle Reactor(ABR)+SBR -

โรงงานสงขลาแคนนิ่งหาดใหญ่

Project Engineering Aqua Nishihara Corporation Limited

Project Name : โรงงานสงขลาแคนนิ่งหาดใหญ่

Project Description :

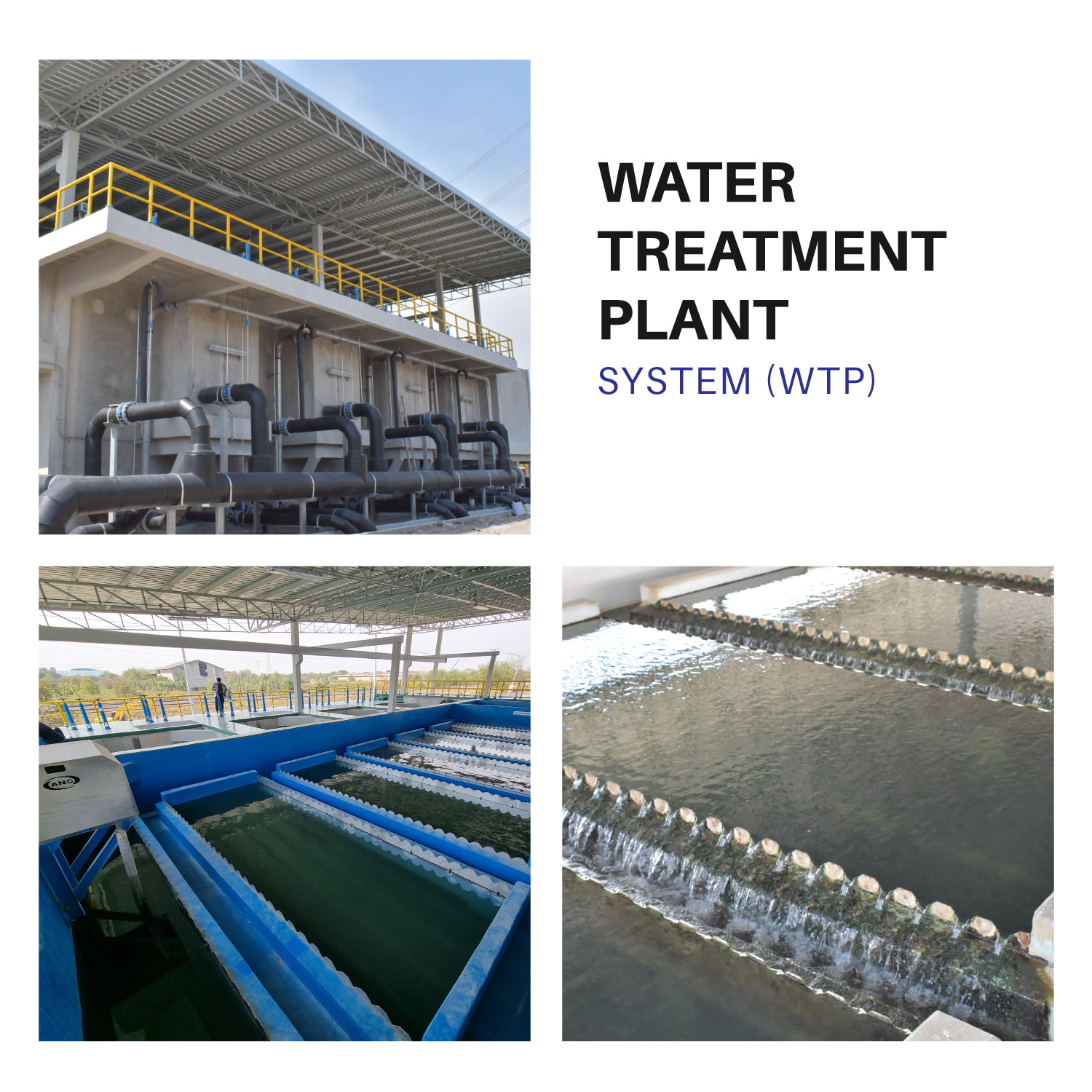

The lamella c200 m3 / hr sedimentation tank is used to increase sedimentation in the wastewater system instead of the traditional sedimentation tank system which takes up a lot of space. -

Thane water distribution station

Project Engineering Aqua Nishihara Corporation Limited

Project Name : Thane water distribution station

Project Description :

Precast concrete tank (Technology from Sweden), size 1700cum, used for collecting tap water. To be a place of increasing pressure Water is pumped to the community. -

Bangkok Hospital

Project Engineering Aqua Nishihara Corporation Limited

Project Name : Bangkok Hospital

Project Description :

Step screen 100 m3/hr waste separation machine is used to separate waste from waste water, bathroom, toilet and various activities. In the hospital before entering the sewage system. -

Green Spot

Project Engineering Aqua Nishihara Corporation Limited

Project Name : Green Spot

Year : 2015

Location : Nong Khae Industrial Estate

Flow Rate : 1,350 m3/d

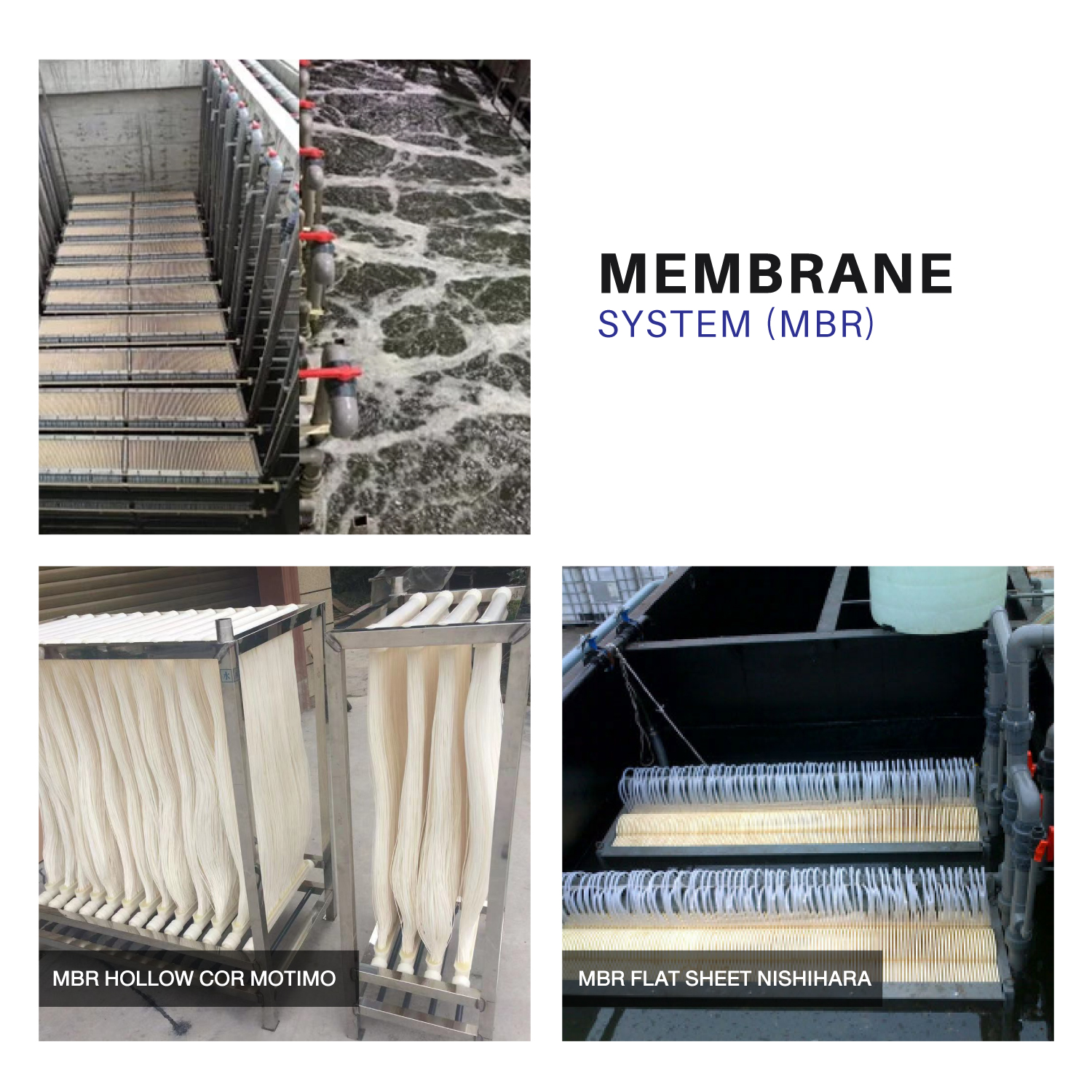

Featured : Oxygen adding by air blower and also stirring with Submersible Mixer. The system saves energy for air supply. Moreover, MBR system is used so the treated water can be recycled.

Technical : An AT Controller series of Fussy Logic controls the duration of time required to fill the air for the microorganisms in the required quantity for microorganism used. (Oxygen Uptake Rate). Consequently, Oxygen dispensed so it was used efficiently and left unused.

Project Description : The Anaerobic Baffle Reactor (ABR) system has a baffle inside the pond to direct the flow of waste water so it will increase the retention time in the pond. In addition, an efficiency for this system will be higher. Intermittent Aeration MBR (IA-MBR) has an anoxic tank and aeration tank in the same pond so an efficiency will high an also energy saving. Furthermore, ultra filtration membrane is also used to separate solids and turbidity from water. -

The Point

Project Engineering Aqua Nishihara Corporation Limited

Project Name : The Point

Year : 2015

Location : On the main road near the Ratchamongkol University of Technology

Flow Rate : 90-110 m3/building

Featured : Submersible aerator, No noise, No need installation area, area saving for good atmosphere.

Technical : Special plastic media to reduce an installation area, tank sizing minimization but the same efficiency, structure and installation cost saving

Project Description : High efficiency with Fixed-Film Aeration system with random flow media, high quality and stability for treated water to make sure that will pass the standard of domestic wastewater. -

Summer Garden

Project Engineering Aqua Nishihara Corporation Limited

Project Name : Summer Garden

Year : 2014

Location : Changwatthana 19 near Central Changwatthana

Flow Rate : 50-60 m3/building

Featured : Aerobic system will used with silent air blower by a vertical tank shape which special design from AQUA around garden and swimming pool, no noise to disturb the natural atmosphere.

Technical : Fixed film aeration sytem

Project Description : NBF-50 and NBF-60 per building

BOD in/out = 250/20 mg/l

SS in/out = 300/30 mg/l -

Marriott Executive Apartments

Project Engineering Aqua Nishihara Corporation Limited

Project Name : Marriott Executive Apartments

Year : 2015

Location : Sukhumvit Park – Bangkok

Flow Rate : 273 m3/d

Featured : Submersible aerator with silencer, No need installation area, area saving for good atmosphere.

Technical : Special design for plastic media, area saving for good atmosphere also minimize the tank size but the same efficiency.

Project Description : High efficiency with Fixed-Film Aeration system with random flow media, high quality and stability for treated water to make sure that will pass the standard of domestic wastewater. -

Ti Rubber

Project Engineering Aqua Nishihara Corporation Limited

Project Name : Ti Rubber

Year : 2011

Location : Klaeng, Rayong province

Flow Rate : STR-20 stick rubber generation 10 t/hr, wastewater 2,600 m3/d

Featured : Get benefits from biogas for cost saving, 900 Nm3/d biogas production.

Technical : Special design for plastic media, area saving for good atmosphere also minimize the tank size but the same efficiency

Project Description : Anaerobic Baffle Reactor(ABR) will used in this project for support the flow variation which cause from the vary amount of rubber. The baffle will used for flow direction setting and also increase retention time. Moreover, fixed-film aeration system also be used which is high efficiency treatment system so you can ensure that the treated water will meet an effluent wastewater standard. -

Santorini

Project Engineering Aqua Nishihara Corporation Limited

Project Name : Santorini

Year : 2011 to Present

Location : Cha-am, Petchburi province

Flow Rate : Wastewater from toilet around 1-35 m3/d, BOD in/out = 250/20 mg/l

Wastewater from restaurant around 3-20 m3/d BOD in/out = 1,200/20 mg/l

Oily wastewater (FOG) in/out = 600/20 mg/l

Featured : Fixed-film aeration system will used which Is an easy operation system but high efficiency and stability. Moreover, enzyme feeding system also be used for grease digestion co-op with fixed-film aeration.

Technical : Silencer air blower be used for this work : easy for maintenance and operation Moreover, feeding enzyme metering pump + control panel also be used.

Project Description : Ready-made wastewater treatment tank for toilet, resident and restaurant which are ST-BF, NBF and AKZ depend on type and quantity of the wastewater. -

After You

Project Engineering Aqua Nishihara Corporation Limited

Project Name : After You

Year : 2015

Location : Sinsakorn Industrial Estate, Samutsakorn province

Flow Rate : Wastewater flow 45 m3/d, BOD in/out = 2,000 / 20 mg/l, FOG in/out = 500 / 10 mg/l

Featured : Ready-made wastewater treatment tank which is customized design for only this project (Model : YAS+MBBR)

Technical : Activated sludge process which uses yeast co-operate with MBBR media. So, the system can treat an oily wastewater with high efficiency and stability also area saving.

Project Description : Silencer air blower be used for this work : easy for maintenance and operation Moreover, feeding enzyme metering pump + control panel also be used. -

Kingfisher

Project Engineering Aqua Nishihara Corporation Limited

Project Name : Kingfisher

Year : 2004

Location : Samut Sakhon

Flow Rate : 4,000 m3/d

Featured : Effective grease digestion system by yeast system. The system work without grease trap or grease digester.

Technical : Specific yeast suitable for grease digestion with no impact for environment.

Project Description : Yeast system can reduce almost 90% of COD in the wastewater. Moreover, the system no need chemical used so the operating cost will be low if compare with dissolved air floation (DAF). For IC process, is the one of easy operate system which can decrease the amount of TKN that contaminated in the wastewater. Furthermore, sludge bulking can be ignored and no need to return sludge. -

Sumi Rubber

Project Engineering Aqua Nishihara Corporation Limited

Project Name : Sumi Rubber

Year : 2010

Location : Muang, Udon Thani Province

Flow Rate : STR-20 stick rubber generation 10 t/hr, wastewater 2,600 m3/d

Featured : Get benefits from biogas for cost saving, 900 Nm3/d biogas production.

Technical : Special design for plastic media, area saving for good atmosphere also minimize the tank size but the same efficiency.

Project Description : Anaerobic Baffle Reactor(ABR) will used in this project for support the flow variation which cause from the vary amount of rubber. The baffle will used for flow direction setting and also increase retention time. Moreover, fixed-film aeration system also be used which is high efficiency treatment system so you can ensure that the treated water will meet an effluent wastewater standard.